-

-

Design

We develop new products through careful conception and creation via hand drawings to feel with strokes and constantly correct completed works. Every piece of furniture and every model are the outcome of the elaborate work created by designers with their best efforts in strict compliance with the principles of ergonomics and structural mechanics.

-

Selection of Materials

We are very particular about the materials we select, for materials decide the grade of products. We select the wood free of black spot, scar, hole and uneven shade to make sure that the products will remain solid, durable and deformation-resistant in the future. For the same kind of materials, we select the one that is higher in quality.

-

-

-

Cutting

We have advanced production equipment and experienced craftsmen, who use calipers to cut materials into parts of high precision according to the dimensions indicated on drawings. During the cutting, the craftsmen follow the natural veins of the raw materials for reasonable cutting to make sure that the materials will not crack or deform after taking shape. The result is that the veins on furniture look natural, fluent, pretty and tasteful.

-

Molding

Supported by the rich experience we have accumulated over the years in the manual making of furniture of abnormal shape, we have integrated traditional handiwork with modern technology to provide the furniture with beautiful appearance, fluent lines, precise proportion and a fine profile.

-

-

-

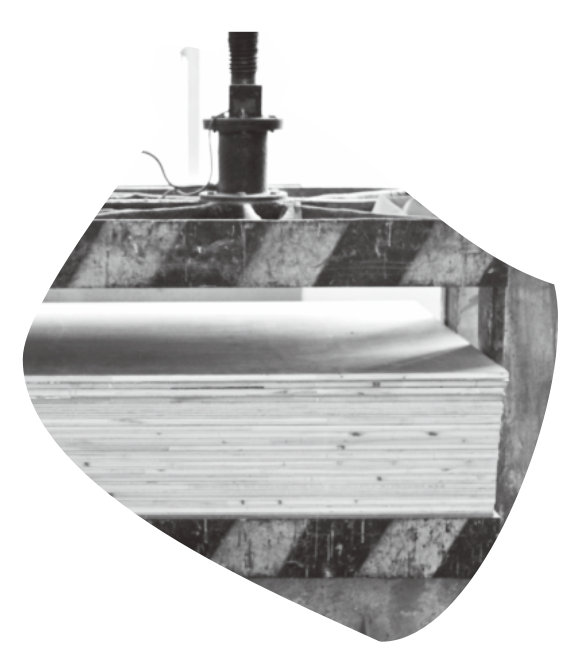

Veneer Press

If the sprayed paint is cosmetics, veneer is the facial expression of human beings that sends the most direct beauty messages. Therefore, we impose harsh requirements on the selection of veneer, which must have consistent overall veins, even thickness and no motley. Glue must be prepared strictly according to proportion and applied evenly onto the boards for flat pasting of veneers. On the thermo press, the duration of pressing is adjusted according to the characteristics of the veneer to finally obtain a piece of materials that is solid and has the same effect as wood.

-

Carving

Carpenters use exquisite techniques and clever hands to carve out every detail. The delicate cutting method, fluent lines and vivid image are so full of vigor that every piece of furniture looks like a refined artware with a longlasting appeal.

-

-

-

Polishing

In the production processes, the products are polished several times to make sure that the wood surface is flat and smooth, with veins that are clearly visible. For the first-time polishing, 120 sand paper is used to polish the white wood to remove any burr and dirt on the surface; for the first-time polishing of primer, 320 sand paper is used; this is then followed by several times of polishing to meet the higher and higher requirement for surface smoothness. The sand paper gets finer and finer until 1200 water sand paper is used finally to give the surface a delicate handfeel, enhance the flatness of the primer, make the lines more fluent and increase the adhesiveness of the finish paint.

-

Paint Spraying

Paint spraying is an important link in furniture making and can best express the craft value of furniture. Before spraying the finish paint, we spray the primer several times first to thoroughly level up the wood surface and enable the furniture to resist yellowing, water and ageing. The polishing serves to ensure the even distribution, uniform color and some fullness of the primer. The exquisite primer process leads to the good adhesiveness of the sprayed finish paint, full varnish, strong resistance against abrasion and yellowing, high hardness, satisfactory glossiness and translucence of products. The solid wood furniture features a transparent paint over the clearly visible veins to provide a strong decorative effect and leave the impression of returning to nature.

-

-

-

Pasting of Gold Foil

We use imported gold foil that has a high content of gold. The pasting thereof strictly follows every process, including grinding, polishing and cleaning of the pasting place, smearing of oil and then imported glue after the oil has dried, pasting of gold foil a few hours later, which is followed immediately by the spraying of oil to protect the foil from oxidization. Several times of spraying will provide the foil with fullness, strong adhesion and bright colors that can resist discoloration for long.

-

Hand painting

The techniques of time-honored elaborate-style painting are used, which has a high artistic effect as the quintessence of the Chinese culture. A complete painting needs to be revised repeatedly before being finalized and then covered with glued Xuan paper or silk. Then, a small writing brush made of weasel’s hair is used to sketch the contour and colors are applied layer after layer to obtain an artwork excelling in both shape and spirit. The work is then blended with glue-stacking effect to give the picture a strong 3D effect. The scenes depicted with the vivid and delicate strokes have high value for appreciation and collection.

-

-

-

Upholstery

The upholstery of furniture is the final process of products and directly passes on the message on whether the appearance of furniture is beautiful and whether its quality is high. We have focused on the R&D of furniture for years and accumulated rich and precious experience in upholstery so that the products can have unique characteristics in the process, obtain a full and beautiful shape, become durable and resist deformation.

-

Assembly

Assembly is a crucial process of assuring product quality. To ensure the precision of assembly and proficiency of operation, we make rational arrangement for every assembly line. The basic process is to assemble the framework first before assembly of the details, which are then adjusted.

-